- 产品简介

- 产品特点

- 产品规格

- 产品尺寸

- 资料下载

- Solid shaft with key

- Solid shaft without key (C0 - C5, starting at C6 on request)

Housing Designs

- Pitch circle diameter

- Round flange

- Square flange

- Foot

Mounting Positions

- Any mounting position.

- You can find the explanation of the mounting positions and the respective quantities of lubricant in the document Quantity of lubricant for gear units ID 441871

Lubricants and Maintenance

- Mineral lubricant CLP ISO VG 220

- Option: Synthetic lubricant CLP HC ISO VG 220

Under normal operating conditions no lubricant change is required for gear unit size C0 to C5 (lubricated for life).

We recommend a change of lubricant for gear unit size C6 to C9 after approx. 10,000 hours of operation.

Paint Finish

- Housing and connector black RAL 9005

- Motor cover b-side magenta RAL 4010

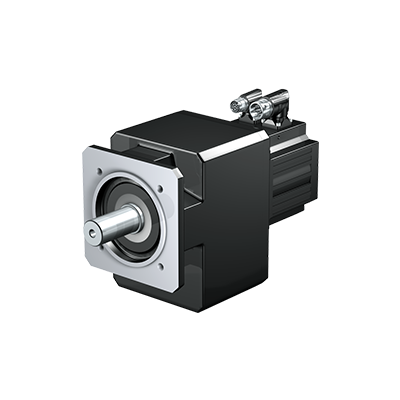

Synchronous Servo Motor EZ

- Extremely compact.

- Highest power per unit volume.

- Large torque.

- High dynamic.

Synchronous Servo Motor EZ

External Fan

- According to DIN EN 60034-6, IC416

- To increase torque and continuous performance.

- In case of higher surrounding temperatures.

- Also available as a retrofit kit.

External Fan

Motor Brake

Optionally the motor b-side can be equipped with a permanent magnet holding brake.

EZ Brake

Encoder

- Optical or inductive measuring principle

- High system accuracy with up to 23 bits resolution

- Up to 4096 recordable resolutions in multiturn version

- Electronic nameplate ensures fast and easy commissioning

- Compatible with STOBER drive controllers and drive controllers of many third-party manufacturers

Resolver

- High temperature resistance

- High vibration strength and shock resistance

Power and Encoder Interface

- Rotating plug connectors with quick lock.

- Option: Supplied with mating connectors.

EZ Connection Method

Encoder One Cable Solution (OCS)

HIPERFACE DSL One Cable Solution (OCS)

- Significantly reduced wiring effort by eliminating the encoder cable

- Significantly reduced space requirements by eliminating the encoder plug connector

- High system accuracy with up to 20 bits resolution

- Up to 4096 recordable resolutions in multiturn version

- Electronic nameplate ensures fast and easy commissioning

- Additional information transferred with the position value

Power and Encoder Interface One Cable Solution (OCS)

- Rotating plug connector with quick lock (connection lines between the encoder and drive controller are routed along in the motor's power cable).

- Option: Supplied with mating connector.

EZ Connection Method (OCS)

Winding Protection

PTC thermistors are installed in STOBER synchronous servo motors as a configuration feature to implement thermal winding protection. This makes it possible for the motor to exceed the maximum permitted winding temperature with the appropriate devices turned off.

Drive Controller Recommendation

- POSIDRIVE MDS 5000 with power range 0.75 to 45 kW

- POSIDYN SDS 5000 with power range 0.75 to 45 kW

- SD6 with power range 0.75 kW to 45 kW

- SI6 with power range 0.75 kW to 25.9 kW

For further information see Drive Controllers

|

Type |

Ratio |

Max. perm. acceleration torque [Nm] |

Stall torque on the gear unit output [Nm] |

Max. perm. input speed in cyclic operation [1/min] |

Backlash [arcmin] |

Torsional stiffness [Nm/arcmin] |

|

C002 |

2 – 50 |

9.7 – 72 |

3.3 – 55 |

6000 |

16 – 20 |

1.3 – 1.6 |

|

C102 |

2 – 70 |

19 – 138 |

6.3 – 106 |

5000 – 6000 |

15 – 18 |

3.1 – 3.9 |

|

C103 |

82 – 111 |

138 |

74 – 101 |

6000 |

15 |

3.9 |

|

C202 |

2 – 70 |

52 – 230 |

22 – 177 |

4500 – 6000 |

14 – 17 |

6 – 8.3 |

|

C203 |

81 – 92 |

230 |

129 – 173 |

6000 |

14 |

8.3 |

|

C302 |

2 – 62 |

114 – 400 |

43 – 309 |

4000 – 5500 |

13 – 16 |

7.1 – 8.7 |

|

C303 |

81 – 137 |

350 – 400 |

131 – 264 |

5500 |

13 |

8.7 |

|

C402 |

2 – 70 |

155 – 600 |

54 – 462 |

3500 – 5000 |

12 – 15 |

17 – 22 |

|

C403 |

81 – 90 |

550 – 600 |

363 – 406 |

5000 |

12 |

22 |

|

C502 |

2 – 70 |

184 – 920 |

65 – 698 |

3000 – 4500 |

12 – 14 |

21 – 23 |

|

C503 |

81 – 135 |

850 – 920 |

362 – 616 |

4500 |

12 |

23 |

|

C612 |

4.2 – 69 |

629 – 1650 |

261 – 1257 |

2800 – 4000 |

10 |

74 |

|

C613 |

49 – 213 |

913 – 1650 |

341 – 1262 |

4000 |

10 |

74 |

|

C712 |

8.5 – 70 |

796 – 2760 |

330 – 1918 |

3100 – 3600 |

10 |

122 |

|

C713 |

51 – 223 |

1548 – 2760 |

642 – 1822 |

3600 |

10 |

122 |

|

C812 |

17 – 69 |

2528 – 4800 |

938 – 2920 |

3200 – 3400 |

10 |

145 – 204 |

|

C813 |

49 – 270 |

1517 – 4800 |

630 – 3600 |

3400 |

10 |

204 |

|

C913 |

78 – 110 |

5628 – 6500 |

2757 – 3917 |

3200 |

10 |

393 |

C Series

- 产品简介

- 产品特点

- 产品规格

- 产品尺寸

- 资料下载

- Solid shaft with key

- Solid shaft without key (C0 - C5, starting at C6 on request)

Housing Designs

- Pitch circle diameter

- Round flange

- Square flange

- Foot

Mounting Positions

- Any mounting position.

- You can find the explanation of the mounting positions and the respective quantities of lubricant in the document Quantity of lubricant for gear units ID 441871

Lubricants and Maintenance

- Mineral lubricant CLP ISO VG 220

- Option: Synthetic lubricant CLP HC ISO VG 220

Under normal operating conditions no lubricant change is required for gear unit size C0 to C5 (lubricated for life).

We recommend a change of lubricant for gear unit size C6 to C9 after approx. 10,000 hours of operation.

Paint Finish

- Housing and connector black RAL 9005

- Motor cover b-side magenta RAL 4010

Synchronous Servo Motor EZ

- Extremely compact.

- Highest power per unit volume.

- Large torque.

- High dynamic.

Synchronous Servo Motor EZ

External Fan

- According to DIN EN 60034-6, IC416

- To increase torque and continuous performance.

- In case of higher surrounding temperatures.

- Also available as a retrofit kit.

External Fan

Motor Brake

Optionally the motor b-side can be equipped with a permanent magnet holding brake.

EZ Brake

Encoder

- Optical or inductive measuring principle

- High system accuracy with up to 23 bits resolution

- Up to 4096 recordable resolutions in multiturn version

- Electronic nameplate ensures fast and easy commissioning

- Compatible with STOBER drive controllers and drive controllers of many third-party manufacturers

Resolver

- High temperature resistance

- High vibration strength and shock resistance

Power and Encoder Interface

- Rotating plug connectors with quick lock.

- Option: Supplied with mating connectors.

EZ Connection Method

Encoder One Cable Solution (OCS)

HIPERFACE DSL One Cable Solution (OCS)

- Significantly reduced wiring effort by eliminating the encoder cable

- Significantly reduced space requirements by eliminating the encoder plug connector

- High system accuracy with up to 20 bits resolution

- Up to 4096 recordable resolutions in multiturn version

- Electronic nameplate ensures fast and easy commissioning

- Additional information transferred with the position value

Power and Encoder Interface One Cable Solution (OCS)

- Rotating plug connector with quick lock (connection lines between the encoder and drive controller are routed along in the motor's power cable).

- Option: Supplied with mating connector.

EZ Connection Method (OCS)

Winding Protection

PTC thermistors are installed in STOBER synchronous servo motors as a configuration feature to implement thermal winding protection. This makes it possible for the motor to exceed the maximum permitted winding temperature with the appropriate devices turned off.

Drive Controller Recommendation

- POSIDRIVE MDS 5000 with power range 0.75 to 45 kW

- POSIDYN SDS 5000 with power range 0.75 to 45 kW

- SD6 with power range 0.75 kW to 45 kW

- SI6 with power range 0.75 kW to 25.9 kW

For further information see Drive Controllers

|

Type |

Ratio |

Max. perm. acceleration torque [Nm] |

Stall torque on the gear unit output [Nm] |

Max. perm. input speed in cyclic operation [1/min] |

Backlash [arcmin] |

Torsional stiffness [Nm/arcmin] |

|

C002 |

2 – 50 |

9.7 – 72 |

3.3 – 55 |

6000 |

16 – 20 |

1.3 – 1.6 |

|

C102 |

2 – 70 |

19 – 138 |

6.3 – 106 |

5000 – 6000 |

15 – 18 |

3.1 – 3.9 |

|

C103 |

82 – 111 |

138 |

74 – 101 |

6000 |

15 |

3.9 |

|

C202 |

2 – 70 |

52 – 230 |

22 – 177 |

4500 – 6000 |

14 – 17 |

6 – 8.3 |

|

C203 |

81 – 92 |

230 |

129 – 173 |

6000 |

14 |

8.3 |

|

C302 |

2 – 62 |

114 – 400 |

43 – 309 |

4000 – 5500 |

13 – 16 |

7.1 – 8.7 |

|

C303 |

81 – 137 |

350 – 400 |

131 – 264 |

5500 |

13 |

8.7 |

|

C402 |

2 – 70 |

155 – 600 |

54 – 462 |

3500 – 5000 |

12 – 15 |

17 – 22 |

|

C403 |

81 – 90 |

550 – 600 |

363 – 406 |

5000 |

12 |

22 |

|

C502 |

2 – 70 |

184 – 920 |

65 – 698 |

3000 – 4500 |

12 – 14 |

21 – 23 |

|

C503 |

81 – 135 |

850 – 920 |

362 – 616 |

4500 |

12 |

23 |

|

C612 |

4.2 – 69 |

629 – 1650 |

261 – 1257 |

2800 – 4000 |

10 |

74 |

|

C613 |

49 – 213 |

913 – 1650 |

341 – 1262 |

4000 |

10 |

74 |

|

C712 |

8.5 – 70 |

796 – 2760 |

330 – 1918 |

3100 – 3600 |

10 |

122 |

|

C713 |

51 – 223 |

1548 – 2760 |

642 – 1822 |

3600 |

10 |

122 |

|

C812 |

17 – 69 |

2528 – 4800 |

938 – 2920 |

3200 – 3400 |

10 |

145 – 204 |

|

C813 |

49 – 270 |

1517 – 4800 |

630 – 3600 |

3400 |

10 |

204 |

|

C913 |

78 – 110 |

5628 – 6500 |

2757 – 3917 |

3200 |

10 |

393 |